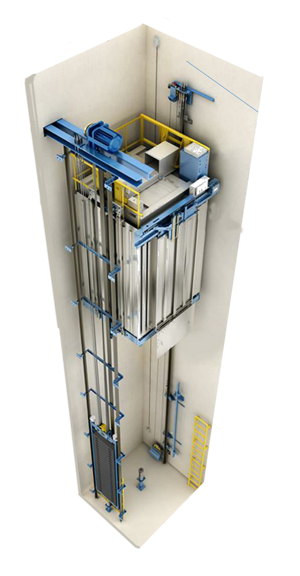

Machine Room Less Elevator

MRLs are a type of traction elevators that do not have a machine room on the top of the hoistway. Instead, the traction hoisting machine is located on the top side wall of the hoistway or on the bottom of the hoistway. The motor is installed with a permanent magnet and works with Variable Voltage Variable Frequency drive. Some hoisting machines use gearless synchronous motors instead of conventional induction motors.

Advantages

- MRLs take up less space in a building since no machine room is required.

- MRLs consume 30% to 80% less power while running than most other types of elevator systems. The power feeders for the MRL are also significantly reduced due to the more efficient design and the counter-balancing provided with traction equipment.

- MRL installations require fewer construction materials and less work time: No well holes to be drilled; no pits to be waterproofed; no requirement for a structural machine- room slab.

- MRLs require significantly less on-site service time than older elevator systems.

- Effective for high load requirements.

- Lowest cost down speed amongst all elevators as gravity is utilized as the motive force.

- No hydraulic oil used – Currently, there are some environmental concerns with oil usage and possible oil seepage or spills, especially in elevators with in-ground jacks.